How to Make Sure Every Parcel Is Labeled and Protected in Your Warehouse

Imagine your warehouse is busy during the cross-border e-commerce season. One wrong label on a parcel can cause confusion. It can also lead to delays or lost inventory. Good secure warehouse management keeps every parcel safe. It employs consistent labeling, careful check-in processes, new technology, and robust security measures. When you follow best practices, you make fewer mistakes, which in turn makes customers happier. The right steps help you track inventory and ensure parcels remain secure:

Benefit | Description |

|---|---|

Inventory Tracking | Using the same labels helps you track items effectively, reducing inventory loss. |

Error Reduction | Correct labels lead to fewer mistakes, enhancing customer satisfaction. |

Security Measures | Security labels prevent counterfeit items and fraud in your warehouse. |

Consider your own warehouse management. Are you prepared for global shipping demands? Fishgoo’s one-stop service exemplifies best practices and sets a standard for secure warehouse management.

Key Takeaways

Consistent labeling helps track inventory well. Clear labels lower mistakes and keep customers happy.

Use strong security to stop theft and tampering. This helps customers trust you and keeps your business safe.

Pick the best label types for your warehouse. Think about moisture and temperature so labels stay on.

Use a step-by-step check-in for each parcel. This keeps inventory correct and stops shipping errors.

Regular inspections and audits keep things safe and efficient. Plan frequent checks to find and fix problems.

Why Secure Warehouse Management Matters

Risks of Poor Labeling and Security

There are many risks if you do not label and protect parcels well. If you use the wrong label or put it in the wrong spot, you might lose track of your items. Labels can fall off or fade if the surface is not ready or if the warehouse is tough on them. If you pick the wrong label material, labels may not last long. These problems can slow down work and make things confusing.

Cause of Poor Labeling | Consequence |

|---|---|

Environmental Exposure | Labels can fall off, fade, or not stick, so you might not know what an item is. |

Surface Preparation Problems | Labels may not stay on, so they can fall off and be hard to read. |

Temperature Issues | Labels may not work in very hot or cold places, which can slow things down. |

Heavy Floor Traffic | Lots of people walking can wear out labels, making them hard to read and causing problems. |

Chemical Spills | Chemicals can break down glue, so labels do not work and you cannot keep track of items. |

Incorrect Label Material | Using the wrong label can make labels fail often, which hurts your work. |

If you do not keep your warehouse safe, you could have theft or tampering. People who should not be there might get in. You could also have fake items or fraud. Without good security, you cannot keep your parcels or your business safe.

Shipping labels must be correct for customs and rules. If you make mistakes, it can cost more money and make customers unhappy.

If customs are slow, packages might be late. This can cost more and make customers upset if they wait too long.

Benefits for Cross-Border E-Commerce

Warehouse security helps a lot with shipping to other countries. When you use clear labels and strong security, your warehouse works better and is safer. You can find things fast and send them out on time. You make fewer mistakes and keep customers happy.

Benefit | Description |

|---|---|

Streamlined Operations | Clear labels help you find things faster and pick orders quickly. |

Accurate Inventory Management | Good labels help you keep track of items and avoid problems with stock. |

Increased Safety | Labels show dangers and help you follow rules, making things safer. |

Labels show what products are and give important details, so things do not get lost.

A good labeling system helps shipping go smoothly and makes sure the right items arrive on time.

Fast and correct order picking is important because customers want their orders quickly.

Warehouse security also helps you avoid mistakes when shipping. You can send orders on time and give good service. If you check things before shipping and use strong security, you make fewer errors. You also talk better with your team and make your warehouse work better. Good security keeps your business safe and helps customers trust you.

Standardized Labeling for Warehouse Inventory Tracking

A good warehouse tracking system starts with clear labels. Using the right labels helps you find and count items fast. This keeps your warehouse neat and your inventory correct. You need to pick the best labels, put them in the right place, and link them to your inventory system.

Choosing Effective Label Types

There are many label types for warehouse tracking. Each type helps in a different way and makes work easier. Here is a table that shows some label types and their benefits:

Label Type | Description | Benefits |

|---|---|---|

Barcode Labels | Clear identifiers for aisles, racks, shelves, and items. | Improves inventory control, order accuracy, and reduces mis-picks. |

RFID Tags | Automated tracking of inventory items. | Enhances efficiency in tracking and managing stock. |

Colour-Coded Labels | Visual cues that communicate information without words. | Reduces confusion and speeds up the picking process. |

Directional Arrow Labels | High visibility labels indicating storage location (above/below). | Eliminates ambiguity in locating items, reducing picking errors. |

Upright Labels | Vertical labels displaying codes for each shelf level. | Allows easy reading of multiple levels without physical strain. |

Summary Labels | Horizontal labels listing multiple location codes at a convenient height. | Simplifies identification of multiple locations at a glance. |

When you pick a label, think about your warehouse environment. Moisture can make labels fall off or swell. Water-resistant adhesives help labels stick in damp places. The glue must match the surface, like plastic or metal, so labels do not peel. Cold warehouses with frost or humidity can also make labels not stick well. Always test labels on your surfaces before using them everywhere.

Tip: The right label material and glue keep labels easy to read and strong. This is important for good warehouse tracking.

Label Placement and Information

Where you put labels is just as important as the type you use. Every label should be easy to see and scan. Put the shipping label on the biggest, flattest part of the package. Do not put labels on seams or corners, because they can peel off or be hard to read. Make sure labels are easy to see and scan for people and machines.

Each label should have information to help you track and manage inventory. Here is what you should include:

Barcode or 2D barcode for scanning

Product name, description, model number, or SKU

Serial number for tracking

Batch or lot number for quality control

Destination and return address

Carrier information

Tracking number for updates

Shipping date

Weight and size

Using all this information makes your warehouse tracking better. It also helps your team find and move items quickly.

Fishgoo uses a careful process for labeling and checking quality. When your product gets to their warehouse, staff put a clear label on each item. They take 3 to 5 QC photos from different sides. You can see these photos online to check the product and label. This step makes sure every parcel is labeled right and ready for the next step.

Note: Easy-to-read, correct labels are the base of good inventory management. They help you avoid mistakes and keep your inventory numbers right.

Integrating with Inventory Systems

You can make your warehouse tracking better by linking labels to an inventory system. Modern systems use barcode and RFID to track items as they move. When you scan a label, the system updates your inventory right away. This removes manual data entry and cuts down on mistakes.

Here is how it works:

This stops mistakes from manual data entry.

The process is faster and makes inventory management better.

Warehouse rack labels help you find products fast. They show SKU numbers, product details, and stock levels. When you link this to your inventory system, you can see your inventory numbers any time. This helps you make better choices and keeps your warehouse running well.

Fishgoo’s system links every parcel label to their digital platform. You can track items, see QC photos, and check inventory online. This gives you full control and is important for cross-border shipping and inventory management.

Remember: Linking labels with your inventory system helps you track items, measure inventory numbers, and keep your warehouse working smoothly.

Parcel Check-In Procedures in Warehouse Management

A strong warehouse management system starts with a clear receiving process. You must check every parcel right when it arrives. This keeps your inventory correct and your warehouse running well. Here are the main steps you should follow.

Step-by-Step Check-In Process

You can use these steps to make your warehouse receiving better and faster:

Prepare for Receiving

Look at your purchase orders and delivery schedules before parcels come. This helps you get ready and stops confusion.Unload and Inspect Parcels

Take each parcel off the truck with care. Check for damage or signs someone opened it. If you see a problem, put the parcel aside for more checks.Accurate Labeling and Documentation

Make sure each parcel has a clear label with a barcode and all needed details. This step helps you avoid mistakes and makes tracking simple.Verify Inventory

Count the items in each parcel. Check them against the shipping papers. Use barcode scanners or RFID readers to do this step faster and keep records right.Quality Control Check

Look inside each parcel. Check for broken or wrong items. Fishgoo’s staff take 3 to 5 QC photos for every item. You can see these photos online to check the product.Update Warehouse System

Put the parcel details into your warehouse management system. This keeps your inventory numbers current.Store Goods Properly

Move the parcels to their storage spots. Follow any special rules for fragile or expensive items.

Tip: Talk clearly with your team to avoid mistakes. Give everyone a job so they know what to do.

Handling Multiple Parcels and Consolidation

Many warehouses get lots of parcels at once. You need a smart system to keep things neat and quick. Here are some ways to help:

Method | Description |

|---|---|

Have a Consolidation Area | Make a special spot for sorting and grouping parcels. This helps you put items for each order together. |

Incorporate Scan Verification | Use barcode scanners to check parcels fast. This helps you find mistakes and makes things quicker. |

Minimize Walking Time | Set up your warehouse so staff walk less. This saves time and energy. |

Use a Warehouse Management System (WMS) | A WMS helps you plan the best ways to pick and store parcels. It also cuts down on mistakes. |

Collaborate with a 3PL | Work with a third-party logistics provider when it is busy. They can give extra help and resources. |

Fishgoo’s warehouse has a special area to group parcels from different sellers. Staff scan each parcel and check the details. You can put many items into one shipment. This saves money and makes shipping to other countries easier. The system updates your inventory right away, so you always know what is in your warehouse.

Keeping things in one place helps your team talk better.

You can keep less inventory, which saves space and money.

Exception Management

Sometimes, things do not go as planned. You might get broken parcels, missing items, or late shipments. You need a clear plan to handle these problems and keep your warehouse strong.

Benefit | Description |

|---|---|

Track shipments right away. See delays as soon as they happen. | |

Make adjustments | Fix problems fast to keep deliveries on time. |

Efficient response to exceptions | Use your warehouse system to get alerts and solve problems quickly. |

Fishgoo’s staff help a lot with exception management. When they find a problem, they write it in the system and take photos. You can see these updates online. This helps you make quick choices and keep your customers happy.

Note: Always teach your team to report and write down problems. This keeps your inventory right and your warehouse safe.

By following these steps, you can make your warehouse receiving smooth and strong. You will keep your inventory right, make fewer mistakes, and help customers trust you.

Technology for Warehouse Inventory Tracking

Barcode, QR, and RFID Solutions

You have different ways to track parcels in your warehouse. Barcode labels, QR codes, and RFID tags all help in their own ways. Barcodes are easy to use and do not cost much. You just need a scanner and some simple training for your team. RFID tags let you scan many items at the same time. This saves time and helps stop mistakes. QR codes can hold more details than regular barcodes.

Here is a table that shows how barcode and RFID solutions compare:

Technology | Advantages | Limitations |

|---|---|---|

Barcode | Cost-effective, simple, precise | Needs line-of-sight, single-item scanning |

RFID | Fast, durable, large data capacity | Signal interference, higher cost, complex setup |

Barcodes are good for most warehouses. You can scan each item and update your inventory fast. RFID tags help you track lots of parcels at once. This is great for busy warehouses. Both choices help you make fewer mistakes and keep things correct.

Tip: Use barcode or RFID scanners to count items quickly and check inventory faster.

Real-Time Tracking and Alerts

Real-time tracking lets you see updates on your parcels right away. You always know where each item is in your warehouse. This helps you find problems and fix them fast. Alerts tell you if something is wrong, like if a parcel is missing or a shipment is late.

With real-time tracking, you manage inventory better and lose fewer parcels. You can see what is happening and make quick choices. Your team can fix problems before they get worse.

Real-time tracking software works with your inventory systems.

Instant alerts help you solve problems and keep things running well.

You can watch shipments and handle delays as soon as they happen.

Note: Real-time data helps you see stock levels better and make fewer mistakes.

Integrating with Warehouse Management Systems

You should connect your tracking tools with warehouse management systems for the best results. When you link barcode or RFID data to your inventory system, your records stay correct and current. This helps you make fewer mistakes and fill orders faster.

Some problems can happen when you connect new systems. Wrong data can mess up your stock numbers. If you cannot see updates right away, orders may be slow. Some workers may not like new systems, so training is needed. You might also need extra IT help to set up new technology.

To stop these problems, buy good software and teach your team well. This helps your warehouse work better and keeps your tracking systems working together.

Tip: Good integration helps you control stock, make fewer mistakes, and keep customers happy.

Warehouse Security and Parcel Protection

Physical Security Measures

Strong warehouse security keeps parcels safe. Use access control systems to stop people who should not enter. These systems use RFID cards or fingerprint scanners. They help you know who goes into each area. Put CCTV cameras with motion sensors in your warehouse. Cameras watch what happens and record any problems. Alarm systems with motion sensors warn you if someone tries to break in. Bright lights make it hard for thieves to hide and help cameras see better. Teach your staff the security rules. When everyone knows the rules, you lower theft and damage.

Put up strong fences and electronic gates around your warehouse.

Check security tools often to make sure they work.

Use barcode or RFID tracking to help stop theft.

A warehouse security checklist helps you check these steps often. This keeps your warehouse safe and protects your inventory.

Value-Added Packaging Services

Parcel protection does not end at the door. You need special packaging to keep items safe when shipping. Fishgoo gives you strong boxes, shockproof wraps, and waterproof covers. These protect parcels from drops, bumps, and water.

Packaging Material | Benefit Description |

|---|---|

Keeps fragile items safe from shocks and shaking. | |

Poly-coated or laminated boxes | Stops water from getting in, good for wet days or damp places. |

Insulated liners and thermal wraps | Keeps food or medicine at the right temperature. |

Water-activated tape (WAT) | Seals boxes tight and shows if someone tries to open them. |

Air pillows | Fills empty space so things do not move in the box. |

Gel-based padding | Soaks up shocks and keeps electronics or medicine safe. |

These packaging choices give more protection to every parcel in your warehouse.

Insurance and Tamper-Evident Seals

You can add more safety with insurance and tamper-evident seals. Insurance pays you if a parcel is lost or broken. Fishgoo lets you buy insurance for your parcels at a good price. Tamper-evident seals show if someone tries to open a parcel without permission. This helps stop theft and keeps parcels safe.

Aspect | Description |

|---|---|

Insurance | Pays you if a parcel is lost or damaged during shipping. |

Tamper-evident seals | Show if someone tries to open the parcel, making it safer. |

Tracking tools (GPS) | Let you see where your parcel is as it moves. |

Digital claims tools | Help you get your money back faster if you need to file a claim. |

When you use these tools, your warehouse security gets much stronger. You keep every parcel safe from theft and damage.

Tip: Check your warehouse security plan often. Change your protection methods when new risks come up.

Staff Training for Secure Warehouse Management

Training on Labeling and Security Protocols

You must teach your team how to keep the warehouse safe and neat. Good training covers many important topics. The table below lists the main things to include:

Component | Description |

|---|---|

Onboarding and Orientation | New workers learn about warehouse rules and their jobs. |

Skills Training | Teaches special skills for jobs like inventory and picking orders. |

Safety Training | Shows how to stay safe and what to do in emergencies. |

Technology Training | Teaches how to use warehouse systems and tools to work better. |

You also need to teach security steps. Security lessons help your team know how to report issues and spot dangers. Awareness programs show how to notice unsafe actions or people who should not be there. Training often helps everyone remember to stay safe and alert.

Tip: Safety lessons done often help stop accidents and keep everyone watching for danger in the warehouse.

Assigning Roles and Accountability

Clear jobs help your warehouse work well. When you give each person a job, they know what to do. For example, chemical handlers and safety workers have their own labeling jobs. If everyone knows their job, they follow the warehouse rules better.

Good labeling means items go to the right place, which helps your business and keeps customers happy.

When you make jobs clear, people take responsibility and follow the rules.

Remind your team that wrong labels can send items to the wrong place. This can hurt your business and make customers upset. Giving clear jobs helps keep workers safe and the warehouse tidy.

Building a Diligent Warehouse Culture

You make a strong warehouse culture by teaching your team to care about safety and security. Start with full training on security steps and awareness. Do regular checks to find weak spots and fix them. Ask everyone to speak up about unsafe things.

Use training that covers security, awareness, and following rules.

Do checks and look for weak spots often.

Let workers report problems and give ideas to make things better.

"When you build a culture where people take responsibility, your warehouse gets safer. Let workers share worries and report unsafe things without being scared."

You can also make a safety group with workers who care about safety. Ask your team for feedback to find what training is missing. Change your safety plan to fit your warehouse. When you do these things, you make your warehouse safer and better for everyone.

Regular Warehouse Inspection and Audits

Doing regular warehouse inspections keeps your workplace safe. It also helps you keep track of your inventory. You need to look around your warehouse often. This helps you find dangers and fix them before they cause trouble. Warehouse inspections are needed for safety and following the rules. If you make inspections a habit, you protect your team, your products, and your business.

Scheduling and Conducting Inspections

Do not wait for something bad to happen before you act. Make a plan to check your warehouse often. Instead of one big audit each year, break it into smaller checks. Try to check your inventory every few months or even every month. Look at busy racks often to make sure they are safe. Regular safety checks help you find dangers and keep everyone safe.

Do audits often, not just once a year.

Check inventory every few months or every month.

Look at busy areas for dangers.

Use safety checks to remind managers and staff.

Make inspections part of your normal routine.

Addressing Issues and Continuous Improvement

Warehouse inspections help you find problems and fix them quickly. When you see something wrong, fix it right away. Do not wait for someone to get hurt. Regular safety checks help stop injuries and protect your things. Audits are not just done once. You need to keep checking important areas like inventory and safety to get better.

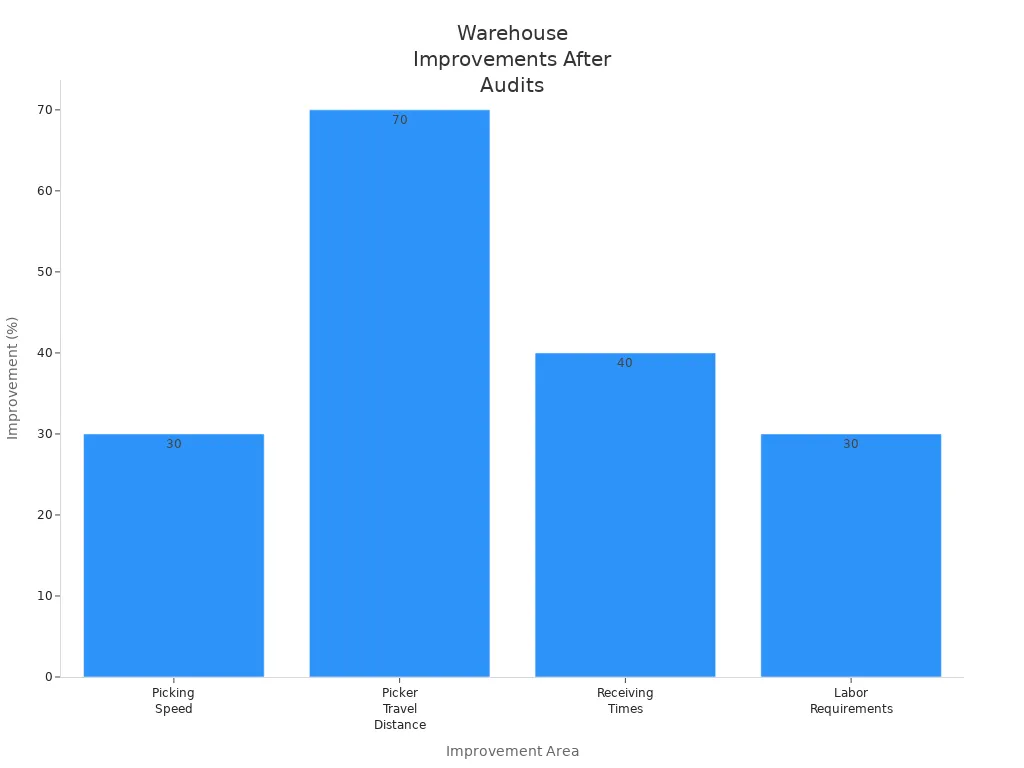

Warehouse inspections can help your team work faster and safer. You can pick items quicker, walk less, and need fewer workers. You also make your warehouse safer by finding dangers early.

Documentation and Reporting

You need to keep good records for every warehouse inspection. Use checklists and reports to track what you find. Checklists help you do the same steps each time. This keeps your safety high and your warehouse running well.

Benefit | Description |

|---|---|

Enhanced Operational Efficiency | Checklists help you finish tasks and avoid mistakes. |

Consistent Quality Control | You follow the same rules every time, which keeps products and orders correct. |

Reduced Equipment Downtime | Regular inspection stops breakdowns and keeps machines working. |

Cost Savings | You save money by avoiding mistakes and keeping inventory right. |

Better Inventory Management | Regular checks stop overstocking and lost items, making inventory inspections easier. |

Warehouse inspections also help you find dangers like blocked doors, wobbly racks, or missing safety lessons. Good records help you see what needs fixing and show how you get better over time.

Tip: Always use a checklist for every warehouse inspection. Look at your reports to spot problems and make your warehouse safer.

You can make your warehouse strong by doing important things. Use standardized labeling and check parcels carefully. Add technology to help track items. Make sure security is strong. Train your staff well and inspect the warehouse often. These steps help your warehouse work well and keep parcels safe. Good management means orders are filled faster and more accurately. You will have fewer missing items and better product condition. Communication with your team gets better too. You can spend less money and make returns easier. Service stays the same every time. Look at your warehouse rules and make them better. Fishgoo’s way shows how to keep parcels safe. Start now and check your labeling and protection systems.

FAQ

What is the best way to label parcels in my warehouse?

Use strong, easy-to-read labels with barcodes or QR codes. Put each label on a flat spot on the parcel. Make sure the label can be scanned and seen easily. This helps you find and track items fast in your warehouse.

How often should I inspect my warehouse for safety?

Check your warehouse at least once every month. Doing regular checks helps you spot problems early. Use a checklist so you do not forget anything important. This keeps your warehouse safe for everyone who works there.

Why is parcel consolidation important in a warehouse?

Parcel consolidation means putting items together before shipping. This saves space and helps you spend less on shipping. It also keeps your warehouse neat and tidy. Your team can manage inventory and get orders ready more easily.

How does technology help with warehouse inventory tracking?

Barcode scanners and RFID tags help you track items right away. You can update your warehouse records quickly with these tools. This lowers mistakes and helps you always know where each parcel is.

What should I do if a parcel arrives damaged at my warehouse?

Move the damaged parcel to a safe spot. Take pictures and write down what is wrong. Tell your warehouse manager about the problem. This helps you fix the issue quickly and keep your inventory records right.

See Also

Understanding Warehouse Services And Their Operational Mechanisms

The Importance Of International Warehouse Services For Global Success

Key Global Shipping Services Every Beginner Should Know