The Complete Guide to Modern Warehouse Management Solutions

Modern warehouse management helps you move goods fast and right. It works well even when goods cross borders. Today, supply chains are global. You deal with hard logistics and more needs. The market for warehouse management systems was about USD 2.88 billion in 2024. It is growing quickly, mostly in Europe. Online shopping and more money make logistics and transport grow more. FISHGOO provides a complete guide to a one-stop system. This system mixes shopping, storage, and delivery, making every step work better and more reliably.

Key Takeaways

Modern warehouse management systems help work get done faster. They use automation and real-time data. This means orders are filled quickly and workers do not need to do as much. This saves money on labor.

Good inventory control, like Just-in-Time and cycle counting, keeps the right amount of stock. It also stops waste and saves money.

Real-time analytics help warehouses spot problems fast. They can fix issues quickly. This makes work better and customers happier.

Picking the best WMS means looking at what your warehouse needs. You should check different vendors. Make sure the system can grow with your business.

FISHGOO gives a full solution for cross-border logistics. It makes shopping and shipping easier. It also makes sure things arrive on time and are good quality.

Modern Warehouse Management Overview

What Is Modern Warehouse Management?

You may ask what modern warehouse management is. Many experts say it means watching over daily warehouse work. This includes how you use space, fill orders, handle returns, and plan worker shifts. Today, a WMS helps you do these jobs on many sales channels. Each channel has its own problems. A good system helps you stay fast and correct.

Modern warehouses use new technology. You can see automation, real-time tracking, and data analytics. These tools help you know your inventory, process orders faster, and make fewer mistakes. When you use these features together, your warehouse gets smarter and more flexible.

Here is a simple comparison:

Operational Aspect | Traditional Warehouse | Smart Warehouse |

|---|---|---|

Order Accuracy | 90-95% (easy to make mistakes) | 99.9%+ (checked by system) |

Labor Costs | High (60-70% of OPEX) | Lower by 30-50% |

Scalability | Limited by space | Grows with cloud |

Response Time | Hours or days for data | Real-time analytics |

Implementation | Low starting cost | Higher first cost |

Why Warehouse Management Matters

Warehouse management is very important in your supply chain. When you use a strong WMS, you move goods faster and more accurately. You also save money and make customers happier. Modern warehouse management lets you track KPIs. This helps you see how well you do and find problems early.

You get these benefits:

Real-time tracking and visibility

Automated inventory management

Faster order fulfillment

Data analytics for better choices

Scalability and flexibility

Focus on worker safety

When you train your team and use the right system, you build a culture of getting better. Everyone knows their goals and works together to fix problems. This leads to better results and a stronger business.

Core Features of a Warehouse Management System

Inventory Control

You need good inventory control to keep things working well. Modern warehouse management systems use many ways to help you track inventory.

Just-in-Time inventory keeps stock low and matches what you need.

Cycle counting checks small parts often, so you find mistakes fast.

Demand forecasting looks at old sales to guess what you need next.

Automated data collection, like RFID and barcode scanning, makes checks quick and correct.

Lean warehousing cuts waste and helps you use space better.

These tools help you avoid running out or having too much stock. You manage inventory better and save money.

Automation and Integration

Automation changes how you do warehouse jobs. Robots and machines pick and pack items much faster. This lowers labor costs and mistakes. Automated systems update inventory right away, so you always know what you have.

Integration links your warehouse management system with other business tools. This makes your work smooth and easy. You see all your data together and make smarter choices.

Tip: Automation and integration help you grow during busy times without needing more workers.

Real-Time Analytics

Real-time analytics give you updates on your warehouse right away. You can see inventory, track shipments, and spot problems early.

Here is a quick look at useful analytics:

Type of Real-Time Analytics | Description |

|---|---|

Inventory Management | Shows stock levels now for quick choices. |

Supply Chain Transparency | Lets you see where products are and if there are delays. |

Predictive Analytics | Warns you about possible equipment or supply chain problems. |

With real-time data, you fix problems fast and keep things running well.

Scalability and Flexibility

A good warehouse management system grows with your business. You can add space or change how you work when you get busy.

Flexible warehouses use space better and lower labor costs.

You can change layouts to match new trends or busy times.

Scalable systems let you grow without big costs or waiting.

This helps you keep customers happy and your warehouse ready for anything.

Feature | Description |

|---|---|

Multi-tenant Cloud Solutions | Lets you grow or shrink easily and saves money. |

Enhanced User Experience | Makes the system simple to use, so you make fewer mistakes. |

Enhanced Support | Gives you help and updates, so your warehouse works well. |

Benefits of Modern Warehouse Management

Efficiency and Cost Reduction

A modern warehouse management system helps you work faster. Automation and integration let you finish jobs quickly and save money. When you use WMS, your warehouse runs better. You spend less on workers and inventory. The system helps you keep track of goods and use space well.

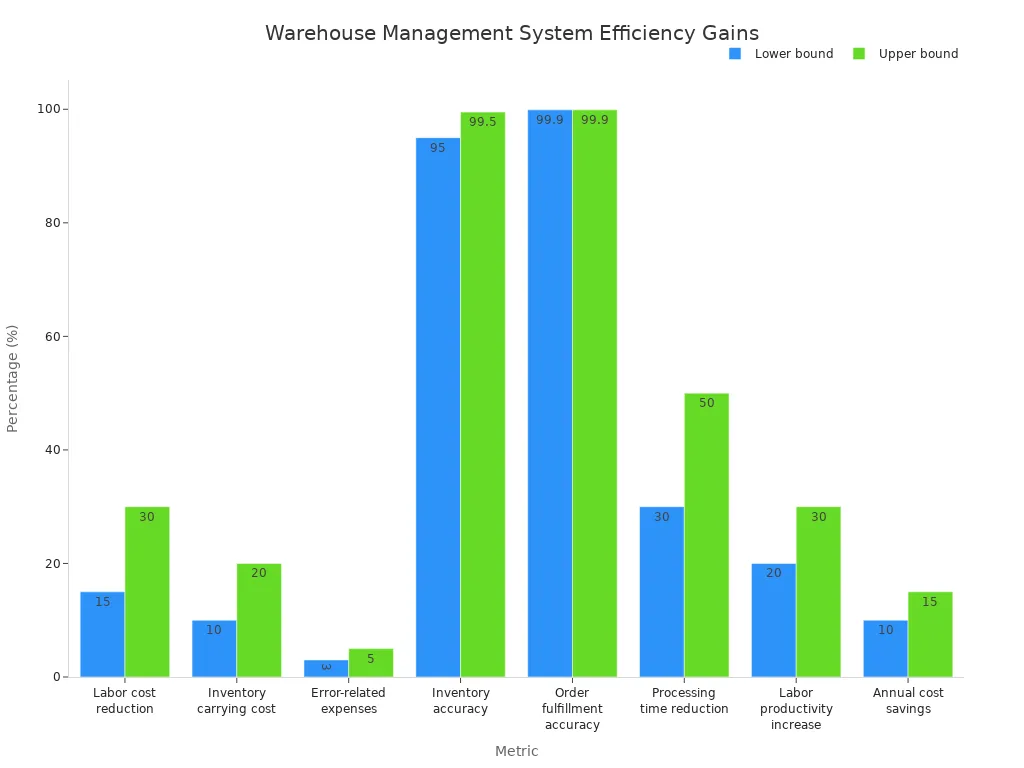

Here is a table that shows how warehouse management systems help you save money and work better:

Metric | Improvement/Reduction |

|---|---|

Labor cost reduction | 15-30% |

Inventory carrying cost | 10-20% |

Error-related expenses | 3-5% of revenue |

Inventory accuracy | 95-99.5% |

Order fulfillment accuracy | 99.9% |

Processing time reduction | 30-50% |

Labor productivity increase | 20-30% |

Annual cost savings | 10-15% |

You can see how much better your warehouse works with the right system. Lower costs and faster work help your warehouse do more.

Enhanced Accuracy

Warehouse management helps you make fewer mistakes. Real-time data lets you watch inventory and orders as they happen. WMS uses AI scanning and automation to check each step. This helps you avoid errors and keep things neat.

Real-time visibility lets you see where items go.

High order picking accuracy means fewer mistakes.

AI scanning technology helps stop human errors.

These tools help you do a better job and have fewer returns. Your warehouse stays correct and works well.

Improved Customer Experience

Modern warehouse management helps you make customers happy. Fast order picking and correct orders build trust. Short dock-to-stock times mean items are ready to ship soon. The perfect order rate shows how well your warehouse sends orders on time and without mistakes.

Watching order accuracy helps you keep customers happy and lower returns.

Customers trust your warehouse when orders are right and on time.

Faster inventory means your warehouse works better.

Good logistics and planning make everything run smoothly.

You get happier customers and better reviews. Good warehouse management helps your business grow and keeps customers coming back.

Selecting a Warehouse Management System

Needs Assessment

First, look at how your warehouse works. Find out what is good and what needs help. Start with a labor check. Labor costs use most of your money. You can use technology to lower these costs. Automation helps you pick and pack items faster. It also helps you store things quickly. Planning is important for now and later. You want your warehouse to work better. You also want customers to be happy. Connecting with supply chain systems helps you see and control more.

Here are the main steps to check your needs:

Check labor and find ways to spend less.

Use automation to make warehouse jobs easier.

Plan well to help your warehouse do better.

Connect supply chain systems for easy data sharing.

Vendor Evaluation

You need to look at vendors before you choose a system. See how each vendor helps your warehouse and order needs. Use a table to compare them:

Criteria | Description |

|---|---|

Scalability | The system should grow with your warehouse and handle more orders and locations. |

Implementation Resources | Check support channels, training, and response times. |

Customer Support | Good support helps you solve problems quickly. |

Pricing | Review costs and see if the system gives a good return on investment. |

Core Functionalities | Make sure the system meets your inventory and order fulfillment needs. |

Integration Capabilities | The system should work well with your current data and supply chain tools. |

User Interface | Easy-to-use software reduces training time and errors. |

Tip: Always ask vendors about their warehouse management experience and how they connect with other systems.

Key Selection Criteria

Pick a system that fits your warehouse needs. Look at both what the system does and how it works. Functional needs include inventory control and delivery management. Non-functional needs are about tech details and vendor help.

Best ways to choose a warehouse management system:

Pick easy software to save on training.

Choose a system that can grow with your business.

Look for good value and long-term help.

Write down what you need from your WMS.

Check each choice for features, price, and help.

Compare costs with how much better your warehouse will work.

Decide after you look at all the facts.

A good system helps your warehouse work better. You fill orders faster and keep things running well.

FISHGOO’s Complete Guide to Cross-Border Warehouse Solutions

FISHGOO’s One-Stop Service Model

You want an easy way to shop from China. FISHGOO helps you buy products and get them delivered anywhere. You just paste a product link into the system. The system lets you buy from top Chinese stores, online or offline. You do not need a Chinese phone number or local payment account. You can pay with PayPal, Visa, or MasterCard. The platform shows product details in English. You always know what you are buying.

After you order, FISHGOO collects your items in a safe warehouse. You can put many products together in one shipment. This saves you money and time. The system checks each item for quality and weight. You get updates at every step. You can ask for help if you need rare items or want to buy in bulk. FISHGOO’s one-stop model covers shopping, storage, checking, and shipping. You get a smooth experience from start to finish.

Note: FISHGOO’s guide helps you avoid common problems. You do not need to worry about language, payment, or shipping.

Warehousing and Logistics Advantages

FISHGOO uses smart warehouse management to help you. The company owns a big overseas warehouse in Spain. The warehouse is 25,000 square meters and is in a key logistics center. Local storage means your goods move faster and arrive sooner. The warehouse uses smart technology to track inventory and manage costs. You get real-time updates on your products.

FISHGOO works with strong partners in logistics. These partners help make delivery faster and more reliable. You can see the main logistics advantages in the table below:

Advantage | Description |

|---|---|

Local Warehouses | FISHGOO uses local warehouses to boost delivery speed. |

Smart Technology | Smart systems help manage costs and track performance. |

Strong Partnerships | Trusted partners make logistics more efficient. |

You get fast, safe, and cost-effective fulfillment. The system supports many shipping lines and covers over 200 countries. This network helps you reach more customers or get your goods quickly.

Quality Inspection and Consolidation

When your products arrive, FISHGOO checks each item for quality. The team looks for damage, checks the weight, and makes sure the order matches your request. You get photos and reports in your account. This step helps you trust the process and know your items are safe.

You can use package consolidation. This service lets you put many orders in one box. You save on shipping costs and reduce waste. The system makes it easy to track each item, even after consolidation. You can add extra packaging or insurance for fragile goods. FISHGOO’s inspection and consolidation services help you get the best value and peace of mind.

Tip: Always check your inspection report before shipping. This helps you catch any problems early.

Global Shipping and Delivery

FISHGOO offers many shipping choices for global customers. You can pick air, sea, or rail transport. The system helps you balance speed and cost. You choose what works best for you. The overseas warehouse in Spain helps speed up delivery to Europe and nearby regions.

Here is a table showing average delivery times for popular destinations:

Destination | Average Delivery Time | Fastest Recorded | Longest Recorded | Most Common |

|---|---|---|---|---|

United States | 5-8 business days | 4 days (DHL) | 9 days (EMS) | 6 days |

European Union | 7-10 business days | 5 days (DHL) | 12 days | 8 days |

Brazil | 9-15 business days | 7 days (FedEx) | N/A | 11 days |

You can track your shipment in real time. The system sends you updates until your package arrives. FISHGOO’s global shipping covers over 200 countries. You get reliable delivery and clear information at every step.

Callout: FISHGOO’s guide gives you control, speed, and safety for every order.

Implementation Steps for Warehouse Management Systems

Planning and Preparation

You begin by making a plan for your warehouse. FISHGOO helps you get ready for success. You look at your warehouse layout and make paths shorter. This saves time for workers. You teach employees how to pick items quickly. You set up checks to make sure every order is packed right. You make clear rules for packing so everyone does it the same way. You use automated reordering to keep enough inventory. You guess what you will need by looking at old sales. Good planning helps your warehouse work well.

Step | Description |

|---|---|

Optimize Pathways | Study and fix warehouse routes to save time. |

Employee Training | Show staff how to pick items fast. |

Quality Control Checks | Check each packed order to make sure it is right. |

Standardized Packing Procedures | Make simple packing rules to stop mistakes. |

Automated Reordering | Use data and machines to restock inventory. |

Demand Forecasting | Guess product needs by looking at sales. |

Data Migration and Setup

You move your data into the new system with care. First, you check your current setup. You ask team members for their ideas and needs. You keep your data safe and follow all rules. You move data step by step and check each part. You use tools to make sure data is correct. You test everything before you start using the system. You give guides and training to everyone. After moving, you watch the system for problems.

Best Practice | Description | Importance |

|---|---|---|

Look at current data, models, and safety. | Helps migration go smoothly. | |

Stakeholder involvement | Ask team members for feedback and updates. | Makes better choices and gets support. |

Data security and compliance | Protect data and follow the rules. | Keeps information safe. |

Phased migration approach | Move data in small steps, not all at once. | Lowers risk and keeps things working. |

Continuous data validation | Use tools to check if data is right. | Makes sure data is good. |

Thorough testing | Test how the system works and feels. | Finds problems before you start. |

Training and documentation | Teach users and give them guides. | Makes learning easy and stops confusion. |

Monitor post-migration | Watch how the system works and fix problems fast. | Keeps things running well. |

Staff Training

You get your team ready for the new system with hands-on lessons. You pick teachers who know warehouse work. You use workshops and role-play to help staff learn. You check how staff are doing and give advice. You split training into small parts so staff can focus. You keep helping staff after training ends. You want everyone to keep learning new skills. This helps your team use the WMS well and work faster.

Training Method | Description |

|---|---|

Staff learn by doing real jobs. | |

Engage Experienced Instructors | Teachers share tips and knowledge. |

Interactive Training Methods | Use workshops and role-play for active learning. |

Regular Assessment and Feedback | Check how staff are doing and help them get better. |

Modular Training | Teach one topic at a time. |

Ongoing Support | Help staff after training is done. |

Continuous Learning Culture | Motivate staff to keep learning new things. |

Compliance and Security

You keep your warehouse safe and follow the rules:

OSHA rules help keep workers safe.

Environmental rules help you use less energy and manage waste.

FDA rules matter if you handle food or medicine.

ISO 9001 helps you keep quality high and customers happy.

Customs and trade rules mean you need good records for global orders.

You follow these rules to protect your business and avoid trouble. FISHGOO’s system helps you stay safe and legal at every step. You can relax and grow your business.

Tip: Always check your compliance list when setting up your WMS. This helps you avoid big mistakes.

Advanced Technologies and Trends

AI and Automation

AI and automation are changing warehouse work. AI helps sort, pick, and pack items fast. Robots move goods from place to place. These machines work all day and night. Your warehouse can stay open longer. You can use a WMS to connect AI tools. This makes jobs quicker and cuts down mistakes. Automation helps track inventory and fill orders fast. You spend less money on workers. You finish more tasks every day.

IoT in Warehousing

IoT makes your warehouse smarter. It links devices and sensors to a network. You see real-time data about goods and equipment. You know where each item is and how it moves. IoT helps with storage, tracking, and transport. RFID tags track goods as they come or go. Smart shelves tell you when stock is low. Sensors watch temperature and humidity to keep products safe. IoT boosts security and lowers the need for workers.

Application | Description |

|---|---|

Real-time visibility | Gives updates about processes, so you can act fast if problems come up. |

RFID technology | Tracks goods in and out, making inventory control easier. |

Autonomous Mobile Robots (AMRs) | Uses AI to move and sort items, making picking and packing faster. |

Smart shelves | Alerts you when stock runs low, so you can restock on time. |

Environmental monitoring | Watches temperature and humidity to keep products safe. |

Enhanced security | Protects goods and reduces theft risks. |

Sustainability Initiatives

You can help the planet with green warehouse practices. Many companies use solar panels and LED lights to save energy. They recycle waste and use water-saving tools. Some warehouses use wind or biomass energy to cut power use. Smart technology and automation help save energy too. These steps make your warehouse eco-friendly and lower costs.

Initiative | Description |

|---|---|

Energy Efficiency | Solar panels, LED lighting, and smart energy systems cut power use. |

Waste Reduction and Recycling | Recycling programs and less waste help the environment. |

Water Management | Water-saving tools and rainwater systems manage resources. |

Renewable Energy Integration | Wind and biomass energy reduce non-renewable energy use. |

Smart Technology and Automation | Sensors and automation optimize logistics and save energy. |

Predictive Analytics

Predictive analytics helps you make better choices. It shows problems before they happen. You can plan labor and resources early. It helps you avoid running out of stock or having too much. You save money by not keeping extra goods. You work better with suppliers because you know what you need. Forecasting helps you use space and equipment well. Customers get orders faster, so they are happy. You can plan for problems and change your work quickly.

Predictive analytics helps you spot bottlenecks early.

You can plan labor and resources before you need them.

It reduces stockouts and overstock risks.

You lower holding costs by knowing which products move slowly.

You improve supplier coordination with better forecasts.

You use labor, space, and equipment more efficiently.

Customers enjoy better service and faster delivery.

You can plan for disruptions and keep your warehouse running smoothly.

Industry Applications of Warehouse Management

Retail and E-Commerce

Warehouse management is important for retail and e-commerce. A WMS helps you see your inventory right away. You find products fast and make fewer mistakes. Your team works quickly, even if they are new. You save money because you do not send wrong orders. Customers get their packages on time. This makes them trust your business.

Real-time tracking helps stop mistakes and saves money.

Packing and picking are easier and faster.

Voice picking technology helps make orders more accurate.

You keep track of inventory and fill orders right.

Workers do jobs where they are needed most.

Manufacturing and Distribution

Manufacturing and distribution need smooth warehouse work. A WMS helps you control materials and finished goods. You plan production better and avoid waiting. The system shows what you have and what to order. You use space well and keep things moving. This helps you finish on time and keep customers happy.

Healthcare and Pharma

Healthcare and pharma have strict rules to follow. A warehouse management system helps you track medicine and supplies. You know where items are and when they expire. The system keeps products safe and ready. You can act fast when there is an emergency. This helps protect patients and meet health rules.

Cross-Border Trade

Cross-border trade has many new problems. You need a warehouse that handles different goods and shipping rules. A WMS helps you with customs papers and tracks shipments everywhere. You can put orders together and pick the best shipping way. This system helps with global shipping and reaching more customers. FISHGOO gives you one easy solution for cross-border management and delivery.

Integration with Supply Chains

End-to-End Visibility

You need to see each step in your supply chain. End-to-end visibility lets you track goods from the supplier to your warehouse and then to your customer. When you use a WMS, you get real-time updates about your products. This helps you spot delays and fix problems quickly. You can use dashboards to watch inventory and order status. With better visibility, you make smarter choices and keep your warehouse working well.

Tip: Use your WMS to set alerts for low stock or late shipments. This helps you stay ready for changes.

Collaboration and Partnerships

You cannot run a supply chain by yourself. You need strong partnerships with suppliers, carriers, and customers. Good teamwork means you share data and work toward the same goals. Your WMS helps you connect with partners and share important information. You can use the system to send updates, track shipments, and solve problems together. When everyone works as a team, your warehouse gets more efficient.

Here are ways to boost teamwork:

Share order and delivery data with partners.

Hold regular meetings to fix problems.

Use your WMS to send real-time updates.

Customer Experience Enhancement

Your customers want fast and correct service. A strong warehouse system helps you meet these needs. When you use integration, you link your WMS with other business tools. This makes order processing faster and more reliable. Customers get updates about their orders and know when to expect delivery. You can also offer better help if problems come up.

Customer Need | How WMS Helps |

|---|---|

Fast delivery | Tracks orders in real time |

Order accuracy | Reduces picking mistakes |

Easy returns | Manages returns smoothly |

When you focus on customer experience, you build trust and help your business grow.

You can make your warehouse better with a modern system. Many companies use WMS to save money and get ahead. The table below shows how technology helps warehouses:

Key Findings | Description |

|---|---|

Awareness of Industry 4.0 | 40-80% of warehouses know about new technology. |

Adoption Rate | 30-60% use these tools every day at work. |

Importance of Technology | Good technology lowers costs and helps you compete. |

FISHGOO is a trusted partner for growing worldwide. Check out FISHGOO’s services to help your business get stronger.

FAQ

What makes FISHGOO different from other warehouse management providers?

FISHGOO lets you do everything in one place. You can shop, store, check, and ship products anywhere in the world. The platform makes paying easy and lets you track your orders live. You get help in English and updates at each step.

Can I use FISHGOO if I do not speak Chinese?

Yes, you can use it. FISHGOO shows all product details in English. You do not need to know Chinese or have a Chinese phone number. The platform uses simple words to guide you through every step.

How does FISHGOO help lower my shipping costs?

You can put many orders into one box. This is called package consolidation and helps you pay less for shipping. FISHGOO also gives you different shipping choices to match your budget and how fast you want your order.

Is my order safe with FISHGOO’s quality inspection?

FISHGOO checks each item for damage and makes sure it is right before sending it. You get photos and reports in your account. This helps you trust that your order is safe and correct.

What payment methods can I use on FISHGOO?

You can pay with PayPal, Visa, MasterCard, or local ways to pay. The platform lets you pay from anywhere, so you do not need a Chinese bank account.

Tip: Pick the payment method that is easiest for you.

See Also

Understanding Warehouse Services: Functions And Operations Explained

The Importance Of International Warehouse Services For Global Success

Key Global Shipping Services Every Beginner Should Know

Maximizing Cross-Border E-Commerce Logistics For International Growth